Cummins announces new X10 engine, next in the fuel-agnostic series, launching in 2026

Cummins Inc. announced it will showcase the next generation of integrated powertrain and digital connectivity at the American Trucking Associations’ Technology & Maintenance Council’s annual meeting and transportation exhibition. This marks the first time that leading fleet professionals from across North America will see a fully-integrated Cummins powertrain: engine, transmission, axles and fuel delivery system to exhaust aftertreatment – all equipped with the latest digital technologies and service features.

“The importance of uptime to our customers is paramount. In addition to powertrain reliability, the digital architecture now available on our products sets a new standard for the industry,” said Brad Sutton, Executive Director – Engineering at Cummins Inc. “Cummins engines now come standard with the ability to notify a customer of a potential component failure up to 90 days before it happens, which allows fleets to proactively address issues during their next scheduled downtime.”

Cummins Digital Capability

Cummins' commitment to internal combustion engine innovation is complemented by its commitment to offering digital products and services that enhance the entire life of every Cummins engine. This includes connecting real-time data from vehicles on the road to maintenance and service operations, giving customers an unparalleled ability to look ahead, streamline operations and minimize downtime.

Cummins customers can expect a digitally enriched experience over the life of their vehicles, including newly released features that connect in-mission operations directly to maintenance and repair processes for more seamless end-to-end fleet management.

These new digital capabilities include industry-first Predictive Service Insights, which alert fleets and service locations when specific components might fail – providing a service recommendation and allowing them to plan a replacement before an actual failure occurs, avoiding unplanned and costly downtime.

Predictive Service Insights are powered by asset-level data directly from the engine and are now available on select 2017 and newer X15 engines, with more engines and predictive features to be added over time. Predictive Service Insights and other new digital features are included with Cummins engines and require no additional integrations or add-ons.

The next generation of Cummins products, and many of today’s products, also have the capability for real-time over-the-air calibration and trim updates, remote monitoring, and an increasing list of other capabilities to prevent unplanned downtime and the costly ripple effects that ensue when a truck is down.

For trucks not equipped with a connectivity device, the same real-time service can be enabled and powered by Acumen®, Cummins’ first-fit smart computing device that offers multiple installation and connectivity options.

Cummins is also constantly updating and enhancing its service tools, including the Guidanz® web and mobile apps, which now offer Fast Track Repair to ensure that repair locations know what is heading to the shop, so technicians and parts are ready, and diagnostics steps are accelerated to get trucks back on the road as quickly as possible.

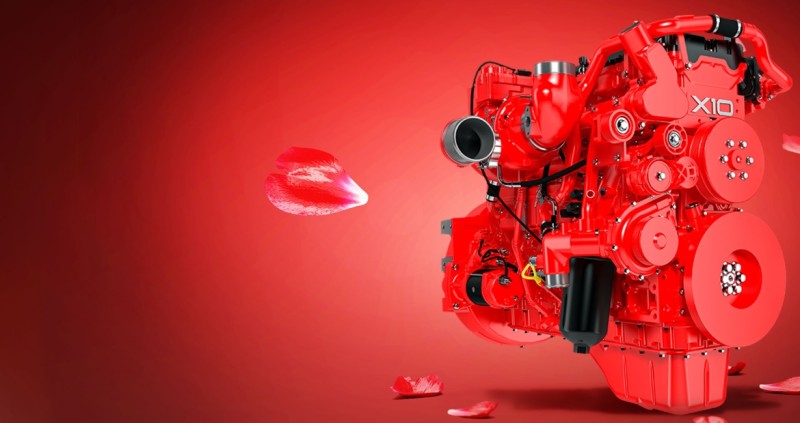

All-New X10™

The next engine in the fuel-agnostic series, the X10, will launch in North America in 2026. This engine, named as part of the X engine family, is uniquely positioned to replace both the L9 and the X12 with the versatility to serve both medium and heavy-duty applications. It will be compliant with U.S. EPA’s 2027 regulations a full year early. The diesel version will be first available, with other versions for gaseous fuels introduced later. This 10-liter displacement product slots into Cummins’ product portfolio complemented by the B6.7 and X15 and will serve vocational, transit, pickup and delivery and regional haul customers.

2024 X15N™

Coming to market in 2024, the X15N natural gas engine delivers diesel-like ratings as well as durability and reliability to allow fleets to significantly reduce their carbon footprint without sacrificing capability. From the inception of the platform, the X15N was designed by Cummins with spark ignition in mind, and it offers the industry a solution toward achieving their sustainability goals, including the ability to run on renewable natural gas. The engine’s exhaust flows through a passive and maintenance free three-way catalyst from Cummins Emission Solutions for optimal simplicity. Natural gas fuel storage is represented by a full-scale display model of a Cummins Clean Fuel Technologies back-of-cab 175 diesel gallon equivalent system.

Eaton-Cummins Endurant HD N™

The Alpha level pre-production X15N engine straight from the factory line in Jamestown, New York, is shown integrated with the Eaton-Cummins Endurant HD N 12 speed automated transmission optimized for natural gas engine performance and enabling digital driver features customers are used to with the X15-Endurant powertrains. The Endurant has the best-in-class lube change interval of 750,000 miles as well as remote diagnostic capabilities.

Cummins-Meritor Axles

Power is then transferred to the Cummins-Meritor 14X™ HE tandem drive axles complete with a propriety lube management system (MLMS) for up to a 1.8 percent efficiency gain over axles not equipped with MLMS. The axles also feature high efficiency spiral bevel gearing and laser welded ring gear and case to prevent oil churning and add even greater efficiency and durability. Steering for this powertrain is delivered by the Cummins-Meritor MFS+™ steer axle equipped with disc brakes and 55 degree wheel-cut turning capability for maximum maneuverability.